-

Researchers in the United States have developed a revolutionary type of metal tube that remains afloat even after severe damage. This innovation, inspired by the Titanic disaster of 1912, could transform naval engineering, offshore energy platforms, and maritime safety worldwide.

Unlike traditional ships that rely on size, weight distribution, and compartmentalization to prevent sinking, these new “unsinkable” tubes focus on the material itself. Ordinary aluminum is treated with advanced chemical and laser processes to create tiny micro- and nanoscale pores on the surface. These pores make the material extremely water-repellent, or superhydrophobic.

When the tubes are submerged, air bubbles become trapped both around and inside the structure. These bubbles act like natural flotation devices, keeping the tubes buoyant even under heavy pressure. The air remains stable thanks to internal partitions, which prevent it from escaping, even if the tube tips vertically.

Laboratory tests revealed remarkable results: even when the tubes are punctured, cracked, or cut multiple times, they continue to float. This is possible because each microstructure retains its own air bubble, ensuring that damage to one area does not compromise the entire system. The principle is similar to certain natural phenomena—some spiders and fire ants trap air bubbles to survive underwater or during floods.

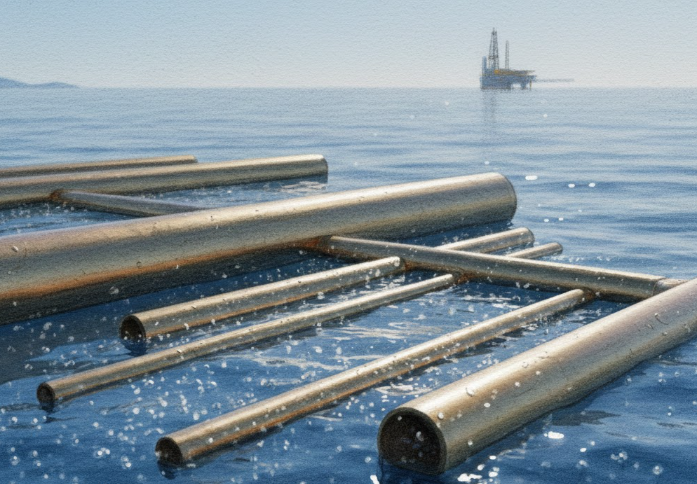

The research team did not stop at individual tubes. They connected multiple units to create floating rafts nearly half a meter long. These rafts remained stable even when additional weight was added, showing the potential for practical applications. Possible uses include modular floating platforms, marker buoys, support bases for ships, and even rafts designed to harness wave energy for electricity generation.

The technology has been tested in turbulent laboratory conditions simulating the open ocean. The results demonstrate that these structures are not only durable but also highly adaptable, capable of maintaining stability under extreme tilts or impacts that would traditionally compromise floating vessels.

This innovation could significantly improve maritime safety by reducing the risk of ship and platform failures. It also opens the door for environmental applications, such as floating solar panels or wave energy converters. The modular design allows engineers to scale structures according to need, making it suitable for small rafts or large offshore installations.

Published in the journal Advanced Functional Materials by the University of Rochester, this research marks a major step forward in material science and naval engineering. While large-scale deployment is still in development, initial results suggest a promising future where floating structures are safer, more sustainable, and more resilient than ever before.

More than a century after the Titanic tragedy, these unsinkable metal tubes may finally make the dream of truly safe, floating structures a reality, combining innovation, safety, and sustainability.